New design suggests a solution for next-gen fusion power plants

01/04/2019 / By Edsel Cook

One of the biggest issues when it comes to designing practical fusion power plants is finding a safe and efficient way to cool it down. MIT researchers have proposed using high-temperature superconducting magnets to expel dangerous heat from the reactor, an article in Science Daily stated.

Their design features a compact fusion reactor with an easy-to-access internal chamber. The parts for the heat-venting mechanism can be swapped in and out of the chamber with ease.

MIT professor Dennis Whyte heads the research team that came up with the new cooling system. He explains that their approach is much more effective than current means of expelling the tremendous heat produced by nuclear fusion. (Related: Physicists unravel the process of magnetic flux pumping to advance the development of fusion energy.)

Finding a better way to cool off fusion reactors

Fusion power has been promising to provide massive amounts of clean and sustainable power for decades. The fuel for this process is lithium and the heavy form of hydrogen, two very common elements that can be extracted from seawater.

An active fusion reactor produces plenty of energy. Eighty percent of this output are neutrons that heat the “blanket” of material around the plasma. In turn, the heat emanating from the blanket will drive a turbine, which generates electrical power.

The remaining 20 percent takes the form of actual heat that is trapped inside the plasma. This heat must be removed from the fusion chamber before it ends up melting the entire reactor.

Plasma can get as hot as the Sun itself. It will melt any man-made material that comes into contact with it. So powerful electromagnets are used to keep the plasma away from the interior walls of the fusion chamber.

Another group of magnets generates a pathway for the plasma’s heat to escape from the chamber. This magnetic side chamber is called a “diverter.”

The secondary magnetic coils responsible for generating the diverter are positioned outside the primary coils. These coils are bigger and stronger so that their magnetic fields can reach inside the fusion chamber.

However, the secondary magnets are much less precise than the primary coils. Their strong output interferes with creating a sufficiently large and efficient heat diverter.

The real-life version of Iron Man’s ARC reactor is here

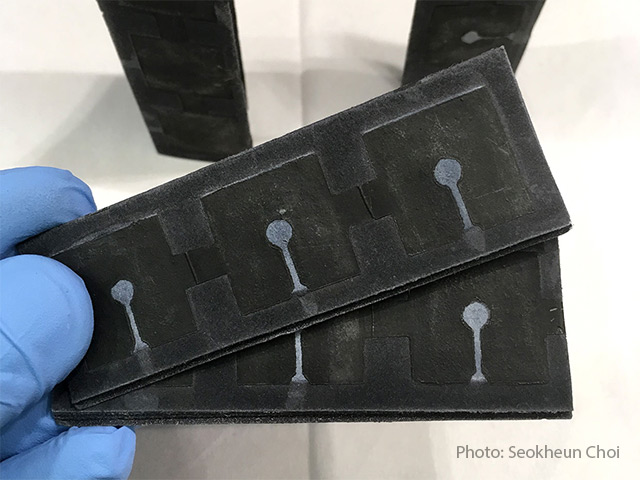

Enter the new reactor design by the Massachusetts Institute of Technology (MIT). The Advanced, Robust, and Compact (ARC) reactor is considered to be the best bet at achieving practical fusion power in the near future.

The ARC design is capable of matching the power output of its bigger predecessors. It is also smaller than the earlier reactors. The combination of small size and high output makes it very hot, so it needs the best cooling system possible.

Whereas the older fusion reactors use two separate sets of solid magnetic coils, the ARC reactor uses magnets that are built in sections. The smaller segments are much easier to remove for repair or replacement.

Despite its smaller size, the ARC reactor has enough space to fit the secondary magnets inside the primary coils. Since the secondary coils are now situated closer to the fusion chamber, they can be made much smaller than the primary coils.

In turn, their smaller size increases the precision with which they can form and shape magnetic fields. The secondary coils can create a longer and larger divertor that can handle the greater heat produced by the ARC reactor.

“You want to make the ‘exhaust pipe’ as large as possible,” Whyte remarked. “It’s really a revolution for a power plant design.”

You can read more stories about fusion energy technology at FutureScienceNews.com.

Sources include:

Tagged Under: electromagnetic field, fusion power, fusion reactor technology, future technology, magnetic field, nuclear fusion, plasma, superconductors